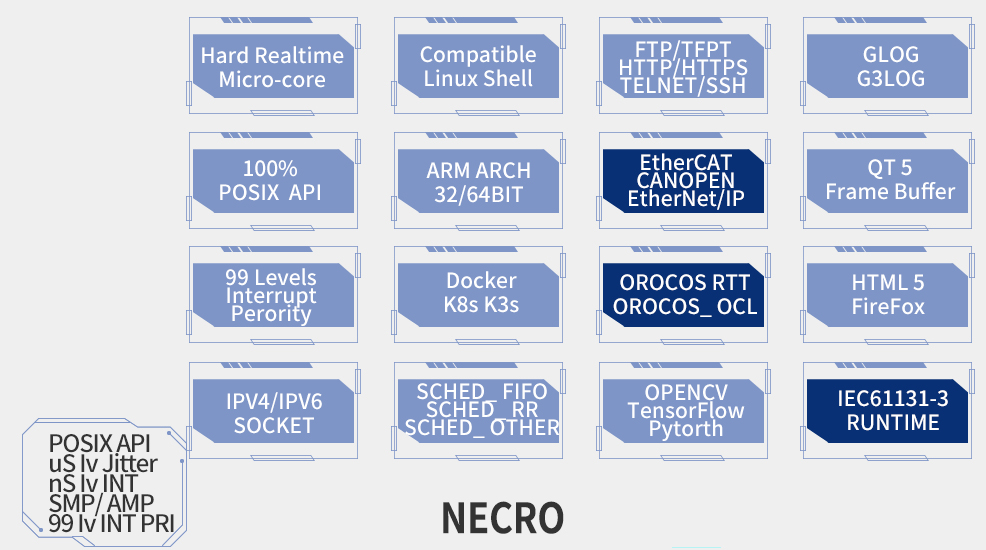

Modern design, future-oriented, always real-time

·100% autonomous code hard real-time microkernel

·Preemptive scheduling algorithm, supporting 99 levels of priority

·US level operating system jitter, nS level interrupt response speed

·100% native POSIX API interface

·Compatible with Linux common commands and shell scripts

·Supports SMP and AMP CPU architectures and isolated cores

·Using IPC and shared memory to achieve inter core communication

·Supports TLS v1 3 and OPEN SSL

·Support national secret encryption algorithms and trusted computing

·Supports mainstream ARM, PowerPC, and X86 chip architectures

·Support GDB remote debugging, support many third-party libraries and algorithms

NECRO industrial real-time operating system is our 100% independent code hard real-time microkernel operating system, NECRO adopts preemptive scheduling algorithm, supports 99 levels of priority, sets pro-nuclear and other features to give customers the most reasonable multi-core multi-threaded program resource allocation mechanism, uS-level OS jitter, nS-level interrupt response speed, to meet the needs of all kinds of high real-time scenarios, 100% native NECRO can achieve perfect compatibility with LINUX, because our compiler emulation with glibc, through __RT() macro switch to confirm the hard real-time with Qiuniu parsing, soft real-time with the emulation of glibc, so that both hard real-time features, but also compatible with Linux non-real-time, we can also provide a strong SDK support, which includes dozens of robot framework such as Orocos rtt, NC special library, and will subsequently support ROS2 and so on. This lowers the learning threshold and cost of use for industrial control customers, improving system real-time and reliability without increasing the development workload of software developers.

NECRO supports EtherCAT, EtherNET/IP, CANOPEN, ProfiNET and other protocols, and supports the first EtherCAT dual master station in China, which can play a powerful role in supporting various types of collaborative robots, composite robots, CNC systems, transport control PLCs and ultra-long maglev tracks, and is the core part of the controller board. NECRO also supports Docker, OPENCV and other types of vision algorithms and frameworks, NECRO is currently working with head robot customers to control industrial robots for spot welding, arc welding, painting, grinding and polishing, 3C assembly, etc., can also be used for medical, cosmetic, industrial applications, commercial and agricultural head collaborative robot controller, but also by the domestic high-end CNC five-axis machining center (NECRO supports NSS runtime, with NECRO Super Studio in industrial automation to achieve the attachment of the controller, used to transport control PLC in lithium new energy, winding, winding, dispensing, to replace Omron such products. NECRO as the most core real-time operating system in the controller segment, has been highly recognized by various customers.

NSS

NSS