Core technology of industrial intelligence

Winding, spot welding, gluing, polishing

Winding, gluing, spot welding, polishing

A winding machine is a device for winding a linear object onto a specific workpiece, usually used for winding copper wire.

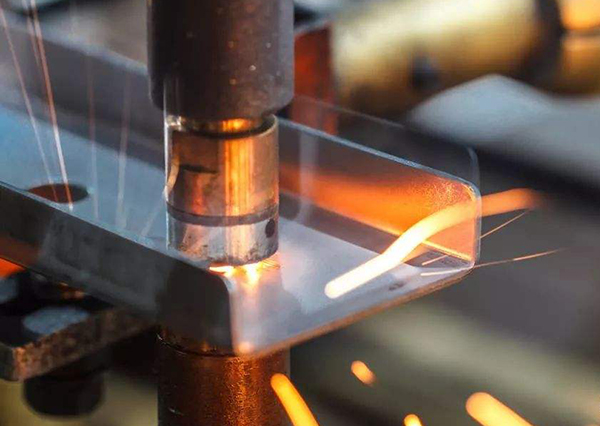

Spot welding refers to a welding method in which a cylindrical electrode is used to form a welding spot between the contact surfaces of two overlapping workpieces during welding. During spot welding, pressure is applied to make the workpiece closely contact, and then an electric current is applied. Under the action of resistance heat, the workpiece contact area melts, and after cooling, a solder joint is formed. Spot welding is mainly used for welding stamping parts of thin plate components with a thickness of less than 4mm, and is particularly suitable for welding automobile bodies, carriages, and aircraft fuselage. However, containers with sealing requirements cannot be welded. Spot welding is a type of resistance welding, mainly used for welding thin plate structures and steel bars.

Dispensing is a process, also known as gluing, gluing, gluing, and dropping. It involves applying, encapsulating, and dropping electronic glue, oil, or other liquids onto a product to allow it to adhere, encapsulate, insulate, secure, and have a smooth surface.

The full name of electric polishing machine is reciprocating electric polishing machine (also known as file mill), which is widely used in the mold industry for finishing and surface polishing. It is a substitute for similar pneumatic products.

Sales E-mail: sales@niic.net.cn

Technical E-mail: support@niic.net.cn

Telephone: 0512-62565029

Website: http://www.niic.net.cn

Address: G2-12, Artificial Intelligence Industrial Park, 88 Jinjihu Avenue, Suzhou Industrial Park, China

Follow us